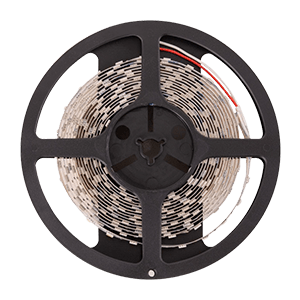

LED Strips

The LED Strips and Tubes are ideal as decorative, ambient or architectural lighting. Different lighting projects can be acquired, where the limit is put by the client's imagination. Available in monocolor, RGB and different powers, they make it a very attractive product to illuminate any space.

To be able to talk about LED strips, we must first talk about the voltage ranges to which they work. We can find 4 ranges of stress that we are going to consider as the main ones. These are: 5 VDC, 12 VDC, 24 VDC and 220 VAC.

LED Strips 5 VDC: Within this range we can include the strips that have direct connection to a USB port and some Digital strips. They are not the most common that we can find in the market, although it is well quote them so that the user knows them.

LED strips 12/24 VDC: The advantages offered by this type of strips is that they can be cut every 5 cm in 12 VDC and 10 cm in 24 VDC. With this type of strips, more precise installations can be made than with the strips of direct connection to the network. An advantage of the same is that, when working in low voltage ranges, the manipulation of them is simpler and less dangerous. On the other hand, one drawback of working with this type of strips is the length of the installations. In GreenIce we recommend not to install more than 10 meters in order to avoid stress drops and therefore loss of illumination.

It is necessary to install a transformer that converts the current that pours the electrical network to the working tension of the strips.

220 VAC LED strips: This type of LED strips are a "modified" version. of the 12/24 VDC strips, so that they can be connected directly to the network through a power outlet. The main advantage, as we have said before, is that these LED strips are connected directly to the electrical network in such a way that we save the annoying transformer. In addition, with this type of strips the problem of the voltage drop does not exist so we can make facilities of 50 linear meters without any problem. Regarding the disadvantages, we can find that with this type of strips you can not make more precise installations because you can only make cuts every meter, so the facilities have to be 1 meter long .

Structure of the LED strips

Led strips are composed of three main elements. These are:

Resistance: The mission of the resistances in the Led strips is to limit the current that reaches the Led diodes. In this way, the current that reaches the chips is adequate and thus ensures proper operation of the strip.

PCB board: The functions of this board is to carry the power supply of the diodes and help to dissipate the heat produced. The quality of the PCB is determined by the thickness of it. The greater the thickness of the same, the greater the quality of the strip. In addition, the greater the thickness of the PCB, the larger it will be. the resistance to breakage of the strip.

LED Chip: Led strips have SMD type chips installed. The acronym SMD means, in its acronym in English, Surface Mounted Device or "Surface Mount Device". There are many types of SMD chips, the most used being the SMD 2835/3528. SMD 5050, SMD 3014 and SMD 5630. The numbers behind the acronym SMD refer to the measurements of the chips themselves. For example, the shape of an SMD 3528 chip is rectangular since its measurements are 35 mm x 28 mm, while the SMD 5050 chips have a square shape since their measurements are 50 mm x 50 mm.

Consumption and brightness

Entering a little more in the matter of the chips that use the Led strips, we will explain in a more detailed way the most used chips in the market and their main uses:

SMD strips 3528/2835.

This chip is used for strips of low power and low consumption. They have a low consumption are usually used in facilities where the light that is required is decorative. They are monochrome strips and the most economic option.

SMD 5050 strips

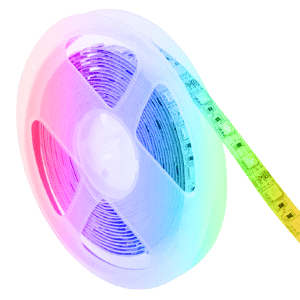

This type of strips have a higher consumption and provide more power than the SMD 3528. They are used for installations, where the luminous requirements are greater than a purely professional lighting. They are monochrome and multicolor strips (RGB).

SMD strips 3014

The most used when the purpose is decorative. They have a higher density of Led's on the strip so that the illumination it provides is of high intensity and continuously. They are strips with a low consumption, but with an exceptional luminous performance.

SMD Strips 5630

They provide a greater amount of light with the same consumption of SMD 5050 strips. They are used for installations where a high luminous power is required. These strips are monochrome and used in professional installations where high power is required.

Amount of LED's per meter

The amount of LED's in the meter directly affects the luminosity provided by the LED strips and their consumption. Depending on the lighting objective that is required, it should be; use one type of strip or another. Then, we show a rule to choose properly the strip that best suits your needs as a function of the LED 's / meter that has the strip.

30 LED's / meter: On-site lighting. Very used to highlight the selected elements in a tenuous way.

60 LED's / meter: Used to provide a standard lighting. Used for integration in moldings, corridors, bar bars, etc.

120 LED's / meter: For when the luminous requirements are high. Widely used for signage, outdoor lighting, etc.

In this category

-

220VAC LED Strip Lights

The 220 VAC LED strips are connected directly to the power grid...

-

LED 12VDC Strip Lights

In the 12 VDC LED strips we can find different versions depending...

-

24VDC LED Strip Lights

Inside the 24 VDC Led strips we can find different versions depending...

-

24VDC LED Strip Lights for Professional Use

The LED Strips for Professional Use are intended for customers who want...

-

Variable Colour Temperature LED Strips

The LED Strips with Variable Color Temperature allow the user to choose...

-

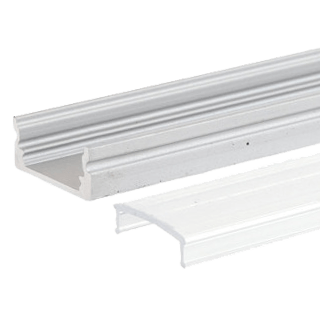

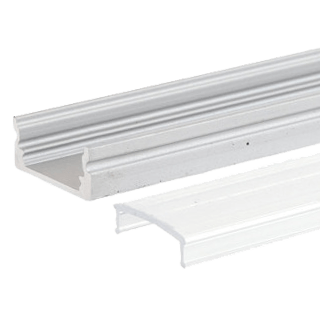

Aluminium and Polycarbonate Profiles for LED Strips

The profiles for Led strips of aluminum and polycarbonate have as their...

-

LED NeonFlex

NeonFlex hoses are a variant of the 220 VAC strips. They have...

-

LED Strip Lights Kit

The LED Strip kits are packages made by the GreenIce team that...

-

Transformers for 12/24VDC LED Strips

The transformer is the most important element when designing a 12/24 VDC...

-

Meanwell Transformers

Meanwell LED Power Supplies allow you to enjoy LED technology optimally. At...

-

Controllers

The Controllers are tools that are optional for Monochrome LEDs but mandatory...

-

Connectors and Accessories

The Connectors and Accessories allow the customer to make modifications, extensions and...

-

LED Strings and Meshes

The main function of the LED Strings and Meshes is the outdoor...

-

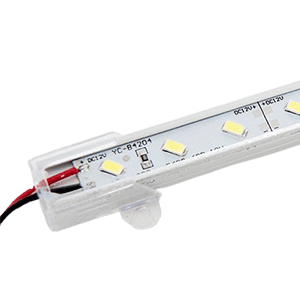

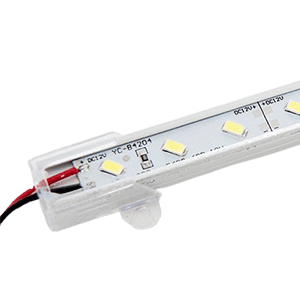

Rigid 12/24VDC LED Strips

The Rigid LED Strips are mounted on an aluminum surface that gives...

-

Twinkly - App Controlled Christmas Lights

Twinkly is the revolutionary LED light string bringing the most advanced technology...

-

Supplier:GreenIce

Profile Aluminum For LED Strip - Diffuser Milky SU-A1707 x 2M

Usual price £8.00Usual priceUnit price / by£17.00Offer price £8.00 Discount -52%Delivery in 48 hCharacteristics- Warranty 3 years

- Facility : IP20

Offer -

Supplier:GreenIce

Strip of 300 LEDs 72W 4,200Lm SMD5050 12VDC IP33 RGB 5M x5M 40,000H [PL-219012-RGB-IP33]-RGB

Usual price £12.00Usual priceUnit price / by£15.00Offer price £12.00 Discount -20%Delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 72.0

- Number and type of LEDs : SMD5050

- Dimable : Yeah

Offer -

Supplier:KIMERA

COB LED Strip 5M 12W/M 960Lm/M 4000ºK IP20 24VDC [SKY-FSLCOB-480L-10mm-W]

Usual price £16.00Usual priceUnit price / by£20.00Offer price £16.00 Discount -20%Delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 12.0

- Luminous efficacy (LM/W) : 80

- Number and type of LEDs : COB 480/M

Offer -

Supplier:KIMERA

Supplier:KIMERACOB LED Strip 5M 16W/M 1520Lm/M CCT (Adjustable Light Shade) IP20 24VDC [SKY-FSLCOB-SS560L-8mm-CCT]

Usual price £26.00Usual priceUnit price / by£40.00Offer price £26.00 Discount -35%Free delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 16.0

- Luminous efficacy (LM/W) : 95

- Number and type of LEDs : COB 560/M

Offer -

Supplier:KIMERA

Strip of 120 LEDs/M 1500Lm/M 6000ºK SMD2835 Self-rectified 220VAC IP65 x50M 40,000H

Usual price £109.00Usual priceUnit price / by£109.00Offer price £109.00 Discount %Free delivery in 48 hCharacteristics- Warranty 5 years

- Power (W) : 15.0

- Luminous efficacy (LM/W) : 100

- Number and type of LEDs : 60 SMD/M

-

Supplier:KIMERA

Self-rectifying COB Led Strip 220VAC 10W/m IP65 - 50 Meters 3M Tape Warm White 3000K

Usual price £198.00Usual priceUnit price / by£202.00Offer price £198.00 Discount -1%Free delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 10.0

- Luminous efficacy (LM/W) : 100

- Number and type of LEDs : 320/M COB

Offer -

Supplier:KIMERA

COB LED Strip 5M 16W/M 672Lm/M RGB IP20 24VDC [SKY-FSLCOB-672L-10mm-RGB]

Usual price £35.00Usual priceUnit price / by£54.00Offer price £35.00 Discount -35%Free delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 16.0

- Luminous efficacy (LM/W) : 42

- Number and type of LEDs : COB 672/M

Offer -

Supplier:GreenIce

COB LED Strip Connector HO-COB220

Usual price £1.00Usual priceUnit price / by£1.00Offer price £1.00 Discount %Delivery in 48 hCharacteristics- Warranty 3 years

-

Supplier:KIMERA

Strip of 320 LEDs/M 50W 5,000Lm CRI90 6000ºK COB 24VDC IP20 8mm Width x5M 40,000H [CA-COB-320-24DC-CW]-Cold White

Usual price £16.00Usual priceUnit price / by£20.00Offer price £16.00 Discount -20%Delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 50.0

- Luminous efficacy (LM/W) : 100

- Number and type of LEDs : COB

Offer -

Supplier:GreenIce

Perfil PC 1 Metro para Tiras 220VAC SMD5050

Usual price £1.00Usual priceUnit price / by£2.00Offer price £1.00 Discount -50%Delivery in 48 hCharacteristics- Warranty 3 years

Offer -

Supplier:GreenIce

Pack 2 Profile Aluminum para LEDs Diffuser Milky Strip 2M

Usual price £15.00Usual priceUnit price / by£34.00Offer price £15.00 Discount -55%Delivery in 48 hCharacteristics- Warranty 3 years

- Facility : IP20

Offer -

Supplier:GreenIce

End Cap for COB LED Strip HO-COB220

Usual price £1.00Usual priceUnit price / by£1.00Offer price £1.00 Discount %Stock available soonCharacteristics- Warranty 3 years

-

Supplier:GreenIce

LED Strip Hose "Neon Flex" 6W 6000ºK 220VAC 8x16mm Simple 120xSMD2835 6W/M x1M 40,000H [HO-NSPVC8x16SOY220CW]

Usual price £4.00Usual priceUnit price / by£6.00Offer price £4.00 Discount -33%Delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 6.0

- Luminous efficacy (LM/W) : 90

- Power factor (PF) : 0.88

(+3)Offer -

Supplier:GreenIce

Profile Aluminum For LED Strip - Diffuser Milky x 1M

Usual price £4.00Usual priceUnit price / by£8.00Offer price £4.00 Discount -50%Delivery in 48 hCharacteristics- Warranty 3 years

- Facility : IP20

Offer -

Supplier:GreenIce

Strip of 300 LEDs 72W 4,200Lm CRI85 6000ºK SMD5050 12VDC IP65 x5M 40,000H [PL219010W]-White

Usual price £14.00Usual priceUnit price / by£21.00Offer price £14.00 Discount -33%Delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 72.0

- Luminous efficacy (LM/W) : 58

- Power factor (PF) : 0.8

Offer -

Supplier:KIMERA

COB LED Strip 5M 12W/M 960Lm/M 4000ºK IP20 24VDC [SKY-FSLCOB-320L-8mm-W]

Usual price £11.00Usual priceUnit price / by£13.00Offer price £11.00 Discount -15%Delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 12.0

- Luminous efficacy (LM/W) : 80

- Number and type of LEDs : COB 320/M

Offer -

Supplier:Kimera

Circular Flexible Neon LED Strip - 220V - Surface Mount - Ø15mm 22W/m x1M IP67

Usual price £7.00Usual priceUnit price / by£9.00Offer price £7.00 Discount -22%Delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 22.0

- Luminous efficacy (LM/W) : 100

- Power factor (PF) : 0.88

(+3) -

Supplier:GreenIce

Strip of 300 LEDs 24W 1,200Lm CRI85 6000ºK SMD3528 12VDC IP65 x5M 40,000H [PL219002W]-White

Usual price £12.00Usual priceUnit price / by£18.00Offer price £12.00 Discount -33%Delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 24.0

- Luminous efficacy (LM/W) : 50

- Power factor (PF) : 0.8

Offer -

Supplier:GreenIce

Strip of 600 LEDs 48W 2,400Lm CRI85 6000ºK SMD3528 12VDC x5M 40,000H [PL219005W]-White

Usual price £11.00Usual priceUnit price / by£19.00Offer price £11.00 Discount -42%Delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 48.0

- Luminous efficacy (LM/W) : 50

- Power factor (PF) : 0.8

Offer -

Supplier:GreenIce

Profile Aluminum For LED Strip For Corners - Diffuser Milky x 2M

Usual price £7.00Usual priceUnit price / by£16.00Offer price £7.00 Discount -56%Delivery in 48 hCharacteristics- Warranty 3 years

- Facility : IP20

Offer -

Supplier:GreenIce

Strip Kit 36W 1,500Lm 150 LEDs 5 meters RGB Blister Transformer, Controller, Bluetooth Control IP20 40,000H [CA-KITRGB-5M]

Usual price £22.00Usual priceUnit price / by£29.00Offer price £22.00 Discount -24%Free delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 36.0

- Number and type of LEDs : High Power

- Dimable : Yeah

Offer -

Supplier:GreenIce

3 in 1 2.4GHz LED Controller Kit [HLP-FUT037SA+]

Usual price £26.00Usual priceUnit price / by£30.00Offer price £26.00 Discount -13%Free delivery in 48 hCharacteristics- Warranty 3 years

- Facility : IP20

Offer -

Supplier:GreenIce

Strip of 600 LEDs 48W 2,400Lm CRI85 6000ºK SMD3528 12VDC IP65 x5M 40,000H [PL219006W]-White

Usual price £17.00Usual priceUnit price / by£28.00Offer price £17.00 Discount -39%Delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 48.0

- Luminous efficacy (LM/W) : 50

- Power factor (PF) : 0.8

Offer -

Supplier:GreenIce

Strip of 300 LEDs 72W 4,200Lm SMD5050 12VDC IP65 RGB 5M x5M 40,000H [PL219012]-RGB

Usual price £13.00Usual priceUnit price / by£16.00Offer price £13.00 Discount -18%Stock available soonCharacteristics- Warranty 3 years

- Power (W) : 72.0

- Number and type of LEDs : SMD5050

- Dimable : Yeah

Offer -

Supplier:GreenIce

LED Strip Hose "Neon Flex" 6W 6000ºK 24V 8x16mm Simple 120xSMD2835 6W/M x1M 40,000H - Cut 5CM [HONSPVC8x16S220CMCW]

Usual price £8.00Usual priceUnit price / by£13.00Offer price £8.00 Discount -38%Delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 6.0

- Luminous efficacy (LM/W) : 90

- Power factor (PF) : 0.88

Offer -

Supplier:GreenIce

Staple LED Strip SMD5050 220-230VAC

Usual price £1.00Usual priceUnit price / by£1.00Offer price £1.00 Discount %Delivery in 48 hCharacteristics- Warranty 3 years

-

Supplier:GreenIce

LED Strip Hose "Neon Flex" 6W 6000ºK 220VAC 8x18mm Double 120xSMD2835 6W/M x1M 40,000H [HO-NSPVC8x16DOY220CW]

Usual price £4.00Usual priceUnit price / by£6.00Offer price £4.00 Discount -33%Delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 6.0

- Luminous efficacy (LM/W) : 90

- Power factor (PF) : 0.88

(+1)Offer -

Supplier:GreenIce

Strip Kit 108W 4,500Lm 450 LEDs 15 meters RGB Blister Transformer, Controller, Remote Control IP20 40,000H [CA-KITRGB-15M]

Usual price £36.00Usual priceUnit price / by£48.00Offer price £36.00 Discount -25%Free delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 108.0

- Number and type of LEDs : High Power

- Dimable : Yeah

Offer -

Supplier:GreenIce

LED transformer 12VDC 24W/2A IP20 [KD-TRIP2524W2A]

Usual price £5.00Usual priceUnit price / by£7.00Offer price £5.00 Discount -28%Delivery in 48 hCharacteristics- Warranty 3 years

- Facility : IP20

Offer -

Supplier:MEANWELL

Supplier:MEANWELLLRS-35-12 Transformer MEANWELL In: 85-264VAC Out: 12VDC 3A 36W Insulation 3750VAC EN60335-1/EN615558

Usual price £19.00Usual priceUnit price / by£19.00Offer price £19.00 Discount %Ask for it and collect it in 5 daysCharacteristics- Warranty 5 years

- Facility : IP20

-

-

Supplier:GreenIce

Strip Kit 72W 3,000Lm 300 LEDs 10 meters RGB Blister Transformer, Controller, Bluetooth Control IP20 40,000H [CA-KITRGB-10M]

Usual price £30.00Usual priceUnit price / by£40.00Offer price £30.00 Discount -25%Free delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 72.0

- Number and type of LEDs : High Power

- Dimable : Yeah

Offer -

Supplier:GreenIce

Profile Aluminum For LED Strip Diffuser Milky 1M WR-1409 x 1M

Usual price £4.00Usual priceUnit price / by£4.00Offer price £4.00 Discount %Delivery in 48 hCharacteristics- Warranty 3 years

- Facility : IP20

-

Supplier:GreenIce

360W LED amplifier [HLP-YS-AMF-T1]

Usual price £5.00Usual priceUnit price / by£5.00Offer price £5.00 Discount %Delivery in 48 hCharacteristics- Warranty 3 years

- Facility : IP20

-

Supplier:GreenIce

Profile Aluminum For LED Strip - Diffuser Milky RL-A1708 x 2M

Usual price £9.00Usual priceUnit price / by£18.00Offer price £9.00 Discount -50%Delivery in 48 hCharacteristics- Warranty 3 years

- Facility : IP20

Offer -

Supplier:GreenIce

Profile For LED Strips 2 meters - Opal Diffuser

Usual price £12.00Usual priceUnit price / by£12.00Offer price £12.00 Discount %Delivery in 48 hCharacteristics- Warranty 3 years

- Facility : IP20

-

Supplier:GreenIce

Strip of 120 LEDs/M 500W 1.000Lm 6000ºK SMD5050 220VAC IP65 x50M 40.000H [HO-220-120-50M-CW]

Usual price £159.00Usual priceUnit price / by£227.00Offer price £159.00 Discount -29%Free delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 500.0

- Luminous efficacy (LM/W) : 100

- Power factor (PF) : 0.8

Offer -

Supplier:GreenIce

Pack 4 LED Strips 72W 4200Lm 6000ºK 300 X SMD5050 12VDC x5M 40,000H [PL219009W-PK4-AP]

Usual price £39.00Usual priceUnit price / by£59.00Offer price £39.00 Discount -33%Free delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 72.0

- Luminous efficacy (LM/W) : 52

- Number and type of LEDs : SMD5050

Offer -

Supplier:GreenIce

Pack 4 LED Strips 72W 4200Lm 4200ºK 300

Usual price £51.00Usual priceUnit price / by£63.00Offer price £51.00 Discount -19%Stock available soonCharacteristics- Warranty 3 years

- Power (W) : 72.0

- Number and type of LEDs : SMD5050

- Dimable : Yeah

Offer -

Supplier:GreenIce

Staple LED Strip SMD2835/5630/RGB 220-230VAC

Usual price £1.00Usual priceUnit price / by£1.00Offer price £1.00 Discount %Ask for it and collect it in 25 daysCharacteristics- Warranty 3 years

-

Supplier:GreenIce

Profile Aluminum For LED Strip For Corners - Diffuser Milky x 1M

Usual price £6.00Usual priceUnit price / by£12.00Offer price £6.00 Discount -50%Delivery in 48 hCharacteristics- Warranty 3 years

- Facility : IP20

Offer -

Supplier:GreenIce

LED transformer 12VDC 36W/3A IP20 [KD-TRIP2536W3A]

Usual price £6.00Usual priceUnit price / by£8.00Offer price £6.00 Discount -25%Stock available soonCharacteristics- Warranty 3 years

- Facility : IP20

Offer -

Supplier:GreenIce

Profile PC Flexible For LED Strip Diffuser Milky x 2M

Usual price £7.00Usual priceUnit price / by£11.00Offer price £7.00 Discount -36%Stock available soonCharacteristics- Warranty 3 years

- Facility : IP20

Offer -

Supplier:GreenIce

SPI Remote Control 2.4GHz [HLP-C6]

Usual price £17.00Usual priceUnit price / by£20.00Offer price £17.00 Discount -15%Delivery in 48 hCharacteristics- Warranty 3 years

- Facility : IP20

Offer -

Supplier:MEANWELL

LRS-35-5 Transformer MEANWELL In: 85-264VAC Out: 5VDC 7A 35W Insulation 3750VAC EN60335-1/EN615558

Usual price £19.00Usual priceUnit price / by£19.00Offer price £19.00 Discount %Ask for it and collect it in 5 daysCharacteristics- Warranty 5 years

- Facility : IP20

-

-

Supplier:GreenIce

Pack 4 LED Strips 72W 4200Lm 6000ºK 300

Usual price £55.00Usual priceUnit price / by£84.00Offer price £55.00 Discount -34%Free delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 72.0

- Luminous efficacy (LM/W) : 58

- Number and type of LEDs : SMD5050

Offer -

Supplier:GreenIce

Profile Aluminum For LED Strip Double - Diffuser Milky x 2M

Usual price £9.00Usual priceUnit price / by£14.00Offer price £9.00 Discount -35%Stock available soonCharacteristics- Warranty 3 years

- Facility : IP20

Offer -

Supplier:GreenIce

Profile Aluminum para Recessed Escayola/Pladur LED Strip 9mm - 1M

Usual price £10.00Usual priceUnit price / by£13.00Offer price £10.00 Discount -23%Delivery in 48 hCharacteristics- Warranty 3 years

- Facility : IP20

Offer -

Supplier:GreenIce

3 in 1 2.4GHz LED Controller [HLP-E3-RF]

Usual price £14.00Usual priceUnit price / by£16.00Offer price £14.00 Discount -12%Delivery in 48 hCharacteristics- Warranty 3 years

- Facility : IP20

Offer -

Supplier:GreenIce

Profile /Luminaire Aluminum 10 X LED Strip - Diffuser Milky x 1M

Usual price £17.00Usual priceUnit price / by£30.00Offer price £17.00 Discount -43%Delivery in 48 hCharacteristics- Warranty 3 years

- Facility : IP20

Offer -

Supplier:KIMERA

COB LED Strip 5M 5W/M 450Lm/M 4000ºK IP20 24VDC [SKY-FSLCOB-480L-4mm-W]

Usual price £23.00Usual priceUnit price / by£35.00Offer price £23.00 Discount -34%Free delivery in 48 hCharacteristics- Warranty 3 years

- Power (W) : 5.0

- Luminous efficacy (LM/W) : 90

- Number and type of LEDs : COB 480/M

Offer

Product comparator

LED Strips

The LED Strips and Tubes are ideal as decorative, ambient or architectural lighting. Different lighting projects can be acquired, where the limit is put by the client's imagination. Available in monocolor, RGB and different powers, they make it a very attractive product to illuminate any space.

To be able to talk about LED strips, we must first talk about the voltage ranges to which they work. We can find 4 ranges of stress that we are going to consider as the main ones. These are: 5 VDC, 12 VDC, 24 VDC and 220 VAC.

LED Strips 5 VDC: Within this range we can include the strips that have direct connection to a USB port and some Digital strips. They are not the most common that we can find in the market, although it is well quote them so that the user knows them.

LED strips 12/24 VDC: The advantages offered by this type of strips is that they can be cut every 5 cm in 12 VDC and 10 cm in 24 VDC. With this type of strips, more precise installations can be made than with the strips of direct connection to the network. An advantage of the same is that, when working in low voltage ranges, the manipulation of them is simpler and less dangerous. On the other hand, one drawback of working with this type of strips is the length of the installations. In GreenIce we recommend not to install more than 10 meters in order to avoid stress drops and therefore loss of illumination.

It is necessary to install a transformer that converts the current that pours the electrical network to the working tension of the strips.

220 VAC LED strips: This type of LED strips are a "modified" version. of the 12/24 VDC strips, so that they can be connected directly to the network through a power outlet. The main advantage, as we have said before, is that these LED strips are connected directly to the electrical network in such a way that we save the annoying transformer. In addition, with this type of strips the problem of the voltage drop does not exist so we can make facilities of 50 linear meters without any problem. Regarding the disadvantages, we can find that with this type of strips you can not make more precise installations because you can only make cuts every meter, so the facilities have to be 1 meter long .

Structure of the LED strips

Led strips are composed of three main elements. These are:

Resistance: The mission of the resistances in the Led strips is to limit the current that reaches the Led diodes. In this way, the current that reaches the chips is adequate and thus ensures proper operation of the strip.

PCB board: The functions of this board is to carry the power supply of the diodes and help to dissipate the heat produced. The quality of the PCB is determined by the thickness of it. The greater the thickness of the same, the greater the quality of the strip. In addition, the greater the thickness of the PCB, the larger it will be. the resistance to breakage of the strip.

LED Chip: Led strips have SMD type chips installed. The acronym SMD means, in its acronym in English, Surface Mounted Device or "Surface Mount Device". There are many types of SMD chips, the most used being the SMD 2835/3528. SMD 5050, SMD 3014 and SMD 5630. The numbers behind the acronym SMD refer to the measurements of the chips themselves. For example, the shape of an SMD 3528 chip is rectangular since its measurements are 35 mm x 28 mm, while the SMD 5050 chips have a square shape since their measurements are 50 mm x 50 mm.

Consumption and brightness

Entering a little more in the matter of the chips that use the Led strips, we will explain in a more detailed way the most used chips in the market and their main uses:

SMD strips 3528/2835.

This chip is used for strips of low power and low consumption. They have a low consumption are usually used in facilities where the light that is required is decorative. They are monochrome strips and the most economic option.

SMD 5050 strips

This type of strips have a higher consumption and provide more power than the SMD 3528. They are used for installations, where the luminous requirements are greater than a purely professional lighting. They are monochrome and multicolor strips (RGB).

SMD strips 3014

The most used when the purpose is decorative. They have a higher density of Led's on the strip so that the illumination it provides is of high intensity and continuously. They are strips with a low consumption, but with an exceptional luminous performance.

SMD Strips 5630

They provide a greater amount of light with the same consumption of SMD 5050 strips. They are used for installations where a high luminous power is required. These strips are monochrome and used in professional installations where high power is required.

Amount of LED's per meter

The amount of LED's in the meter directly affects the luminosity provided by the LED strips and their consumption. Depending on the lighting objective that is required, it should be; use one type of strip or another. Then, we show a rule to choose properly the strip that best suits your needs as a function of the LED 's / meter that has the strip.

30 LED's / meter: On-site lighting. Very used to highlight the selected elements in a tenuous way.

60 LED's / meter: Used to provide a standard lighting. Used for integration in moldings, corridors, bar bars, etc.

120 LED's / meter: For when the luminous requirements are high. Widely used for signage, outdoor lighting, etc.

Subscribe and get discounts and promotions

Subscribe to the Newsletter at the time of purchase and get a 5% discount on your order.

- When selecting an option, the entire page is updated.

- It opens in a new window.